Meat Production is an excellent market segment for Hybrid High temperature heat pumps.

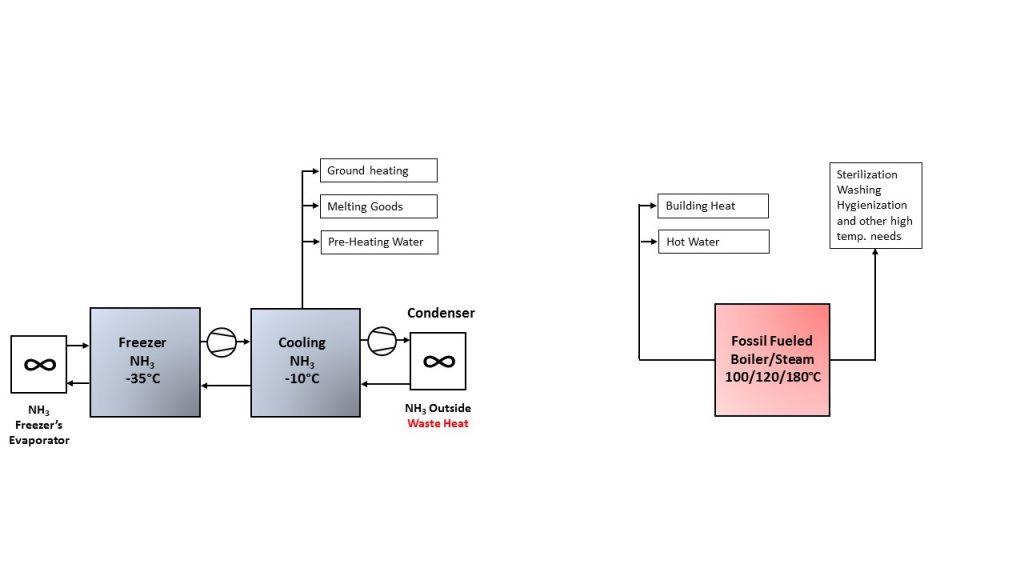

Larger meat production facilities have ammonia freezing and coolers equipment for making cold liquid ammonia for cooling of products and space. They also have a large need for hot water for sterilization or as tap water. The coolers have waste heat in the condenser’s which have a temperature above the ambient temperature. Traditional meat factories often utilize waste heat from the condensers to pre-heat tap water of feed water to the boilers. Their heat is produced in boilers producing steam or hot water which is distributed in the factory.

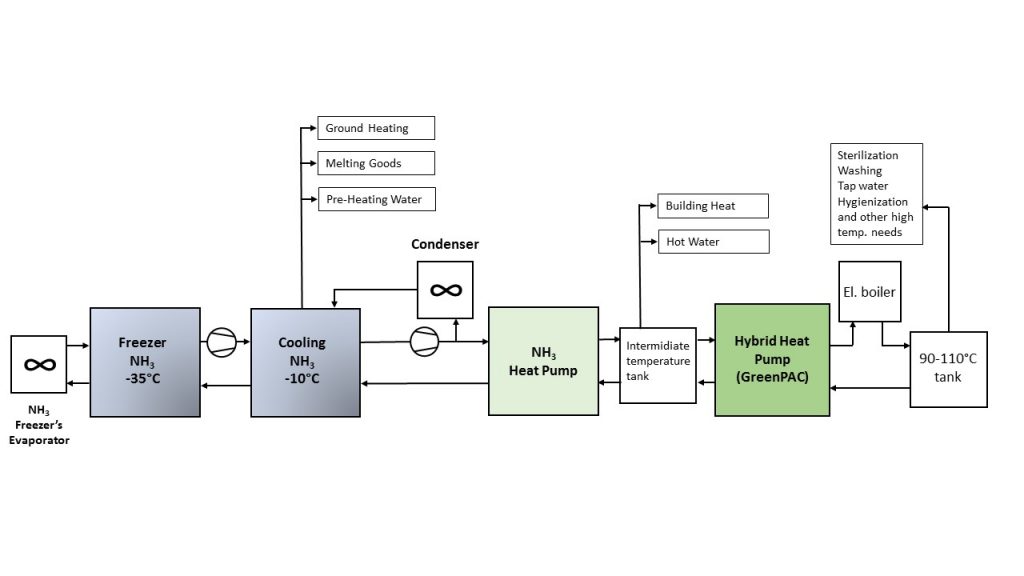

However, the most energy efficient and more modern slaughterhouses recover the waste heat from the chillers to feed thermal waste energy into heat pumps for intermediate temperatures. The heat which is not used at intermediate temperatures can be utilized in high temperature hybrid heat pumps and make water at 85°C or up to 110°C degrees. For optimized running time and energy recovery thermal accumulation tanks are used between the different steps for the heat pumps. The thermal accumulation tanks equalize quick fluctuations in the cooling and heating needs and energy cooling needs at different time of the 24 hours day. The washing period usually starts at the end of the day often into nighttime.

TRADITIONAL MEAT PROCESSING PLANT

MEAT PROCESSING PLANT WITH HYBRID HEAT PUMP: