Arla Arinco, Denmark

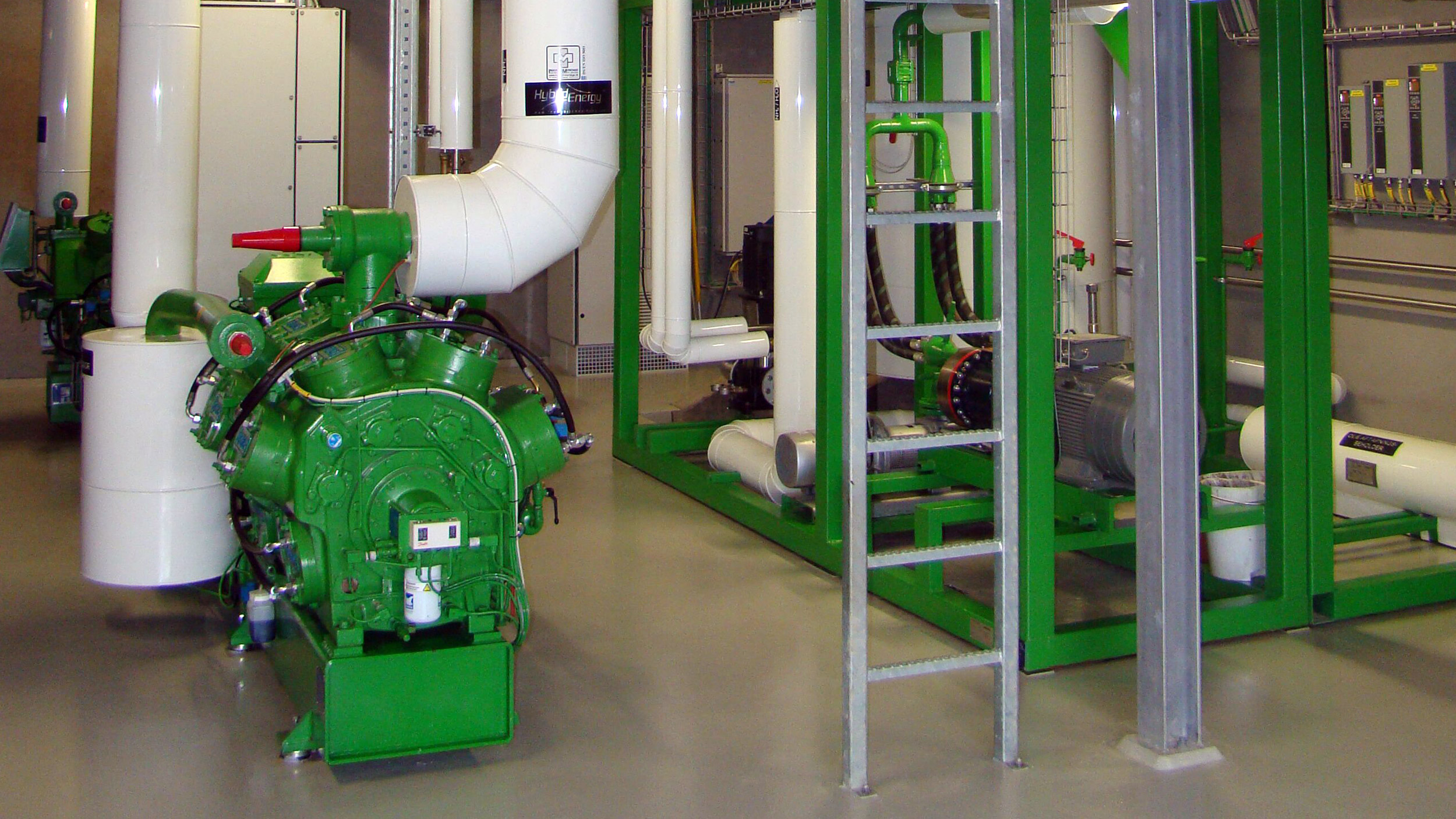

Each year Arla’s dry milk plant in Videbæk uses tremendous amounts of energy in their production. In 2012 they installed a Hybrid Heat Pump of 1,200 kW, recovering waste heat from the evaporation process used to heat up process air.

Instead of cooling the evaporator with water from cooling towers, the excess heat from the cooling process is used to pre heat air to the driers. With a repayment period of 20 months, the Hybrid Heat Pump yields annual energy savings of 4.6 GWh and an annual CO2-reduction of 1,400 metric tons.

Industry

Dairies

Application

Drying

Temperatures °C

45/22, 55/85

Effect

1,200 kW

COP heating (seasonal)

4.5